Solutions

Smart factory space, data, and conditions and the three major elements of a smart environment. A smart factory employs technological solutions that collect, monitor, evaluate, and sort out data with accuracy and in real time. wireless sensing equipment is used to detect important elements, processes, and events, and monitor and manage related data, such as the precise location of the target persons and objects on the factory floor, or environmental data. The equipment is easy to deploy and allows for seamless tracking of the target persons and objects and monitoring of environmental parameters.

Technical principle

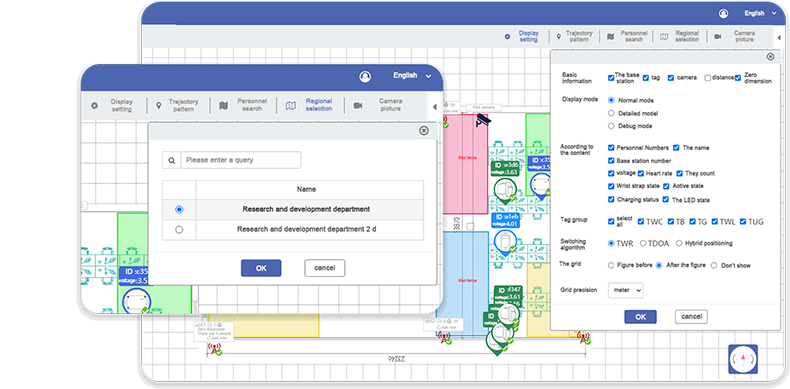

The UbiBot platform perfectly integrates intelligent sensing devices and the Internet. intelligent sensing devices access the platform, collect the target data and transmit it to the UbiTrack platform, where the positioning or environmental data is analyzed and processed. The platform then provides feedback to the user in the relevant form, such as over-limit alarms. The platform can be accessed by mobile phones, computers, and other communication devices.

UWB positioning anchor is deployed in the factory area. The tracking tags are attached to the target persons or objects. The system can accurately locate the position of the tracking tag in real time, and display the positioning information of people, vehicles, or objects on the screen in the factory control center without delay. This system can be used to carry out the control of a safety area, to monitor personnel on duty, or to monitor real-time trajectory of vehicles. Accuracy up to 10cm.

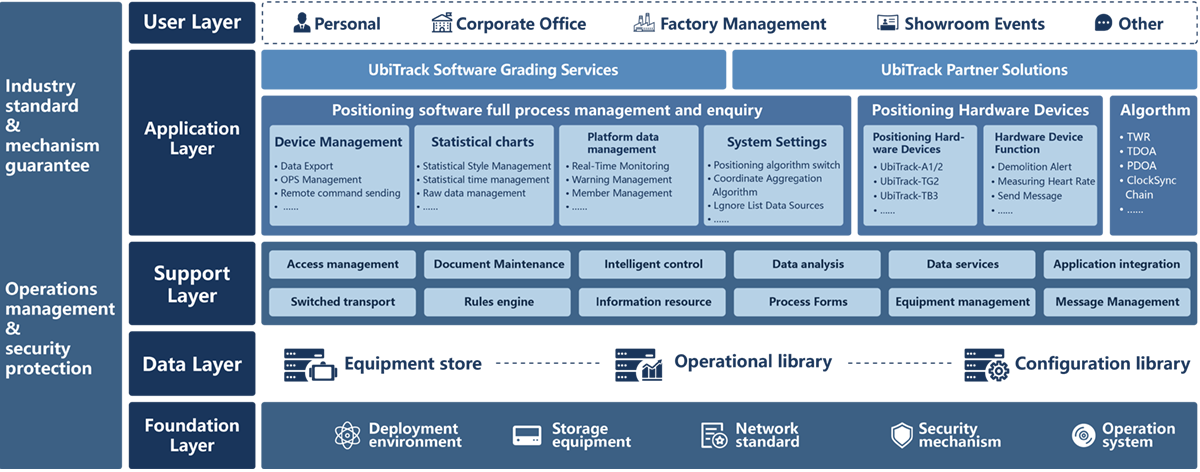

System Design

Our data monitoring and management system for industrial manufacturing parks is based on the private cloud deployment model. It employs wireless sensing equipment that efficiently and accurately monitors and collects data in real time. Linking UbiTrack and UbiBot platforms allows for real-time interoperability of collected data, visualization of positioning data, traceability of historical data, and combining multiple algorithms. Our platforms enable factories and manufacturing parks to achieve comprehensive supervision and control of important parameters, such as exhaust gas and wastewater levels, and to timely adapt and strengthen worker safety measures.

Case Study

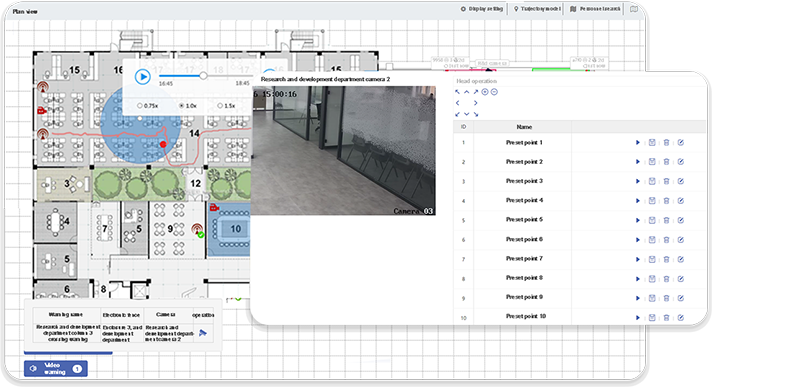

All the data, including data regarding the location of target persons or objects, production hours, inspection trajectory, and other relevant data, is recorded and integrated. Historical data is easily accessed and displayed in a visually convenient manner, allowing for efficient tracking and manageing of the data.

Advanced service

UbiTrack Partner Solutions

UbiTrack Partner Solutions

Building upon the mature product and diversified applications of the UbiTrack positioning system, UbiTtrack has launched Partner Solutions, you can get the hardware API and settings of the UbiTrack system and access to the private platform.

UbiTrack Software Grading Services

UbiTrack Software Grading Services

Building upon the mature product and diversified applications of the UbiTrack positioning system, UbiTtrack has launched the Software Grading Services. These are providing personnel management features, alarm information, 3D view, and many other features.